EHS 2000 Series - Position Specific

The 2000 Series consist of trainings that are required for specific job descriptions. You can find out if your job is required to take these courses by using the Safety Training Matrix Flowchart.

Contact Us

- Environmental Health and Safety

Coastal Carolina University

470B Allied Drive

P.O. Box 261954

Conway, SC 29528-6054

843-349-2770

- View Campus Map »

- Report a Safety Concern »

EHS 2004 Electrical Safety

Electrical Safety training is designed for the specialized employee who works with or around electrical hazards and is a comprehensive look at electrical hazards. The goal of this course is to raise awareness and help prevent common electrical injuries. All persons who install, maintain, repair, or just work near electrical powered equipment will benefit from electrical safety training. Employees required to take this training are also required to take EHS 2031 CPR and AED Safety.

EHS 2005 Respirator Training [PPE]

Designed for any employee or student who wears a respirator in the workplace, this course will teach you the basics of respiratory protection and how to use it on the job. It will cover potential inhalation hazards, the different respirator types and their uses, how to fit test a respirator mask, and respirator care and maintenance. This course is followed by a scheduled respirator fit-testing that must be passed before the use of a respirator is authorized.

EHS 2006 Hazardous Communication

EHS 2007 Laboratory Safety

Lab safety is required for all employees and graduate students who work in laboratories around campus. This course encompasses safety practices to recognize workplace hazard identification, avoidance, and control within a lab setting and introduce the CHP. These practices help instill a safety culture that reduces accidents for employees and promote a safe work environment. This training also informs employees how and when to use many types of personal protective equipment.

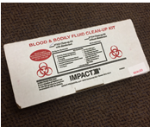

EHS 2015 Bloodborne Pathogens

This training is designed for all employees who may be exposed to blood and body fluids during the performance of their work and who require a basic understanding of bloodborne pathogens, prevention of occupational exposure, and exposure follow-up. This course is for custodial and other employees and staff who manage or clean up spills of human blood or other potentially infectious materials and bodily fluids.

This training is designed for all employees who may be exposed to blood and body fluids during the performance of their work and who require a basic understanding of bloodborne pathogens, prevention of occupational exposure, and exposure follow-up. This course is for custodial and other employees and staff who manage or clean up spills of human blood or other potentially infectious materials and bodily fluids.

EHS 2022 Permit-Required Confined Spaces

For employees who are required to enter confined spaces to do their work, this course provides information on the hazards associated with confined spaces. It will provide employees direction on the proper identification procedures for entrants and attendants as well as proper rescue procedures associated to confined spaces.

EHS 2023 Control of Hazardous Energy (Lockout/Tagout)

Injuries resulting from the failure to control hazardous energy sources during normal work activities can be serious or fatal. This training provides employees with the appropriate lockout/tagout (LOTO) practices and procedures used to prevent the release of hazardous energy. This training is required for electricians, plumbers, HVAC, or any personnel who work on or around electrical, steam, pressure, hydraulic, mechanical, pneumatic or other to conduct maintenance or repair work on systems. Employees required to take this training are also required to take EHS 2031 CPR and AED Safety.

EHS 2024 Scissor and Boom Lift Safety

This training is for specialized pieces of equipment that require "qualified" operators to be trained. Topics include parts of a lift truck, operation, traveling and maneuvering, load handling, environmental considerations and hands-on practice. This is required for all employees who work with powered platforms, manlifts and vehicle-mounted work platforms.

EHS 2025 Powered Industrial Trucks (Fork Lift) Operations Training

This online course for all employees who operate forklifts covers inspection and safe operation of powered industrial trucks. This course will teach you about the operational differences between a car and a forklift, power sources, capabilities, stability, and carbon monoxide hazards while operating propane or diesel trucks inside buildings.

Prerequisite for EHS 3025

EHS 2027 Cranes, Derricks, Hoists, Elevators, Conveyors Safety Training

This hands-on course is designed for employees who will be operating cranes, derricks, hoists, elevators or conveyors. It is an evaluation to ensure a safe operation and knowledge of the equipment.

EHS 2030 Powered Industrial Trucks (Fork lift) Operator Skill Assessment

This hands-on course for all employees who operate forklifts covers inspection and safe operation of powered industrial trucks. This course will teach you about the operational differences between a car and a forklift, power sources, capabilities, stability, and carbon monoxide hazards while operating propane or diesel trucks inside buildings.

EHS 2042 NFPA 70E Safety Training

The aim of this program is to provide comprehensive training to high-risk workers (i.e. skilled trades and maintenance workers) to help the prevention of serious injuries from electrical arc flash hazards at their worksites. Participants will develop understanding of the requirements of OSHA and NFPA, 70E and will be able to identify and reduce or eliminate electrical safety hazards in their workplace. Electrical Safe Work Practices including electrical safety principles, guidelines for qualification of personnel, job planning requirements and management and personal responsibility will be covered.

EHS 2044 AAA Drivers Improvement Program (DIP) (in-class)

EHS 2045 Fire Extinguisher Training (in-class)

This hands-on training course will teach you how to use a portable fire extinguisher. Each participant will use an extinguisher to suppress an actual or simulated fire using the PASS method (Pull, Aim, Squeeze, Sweep). This course is offered outdoors and is intended to supplement online training, a prerequisite. This is designed for higher risk individuals who work in kitchens, plumbing, roofing, cutting and welding trades, or other work with flammable, pyrophoric, reactive materials and similar hazardous materials where a potential fire is more likely.

EHS 2046 Radioactive Material Safety

This course is an overview of DOE rules and regulations set in place to prevent hazards from hazardous materials which are considered any substance or compound that has a capability of producing adverse effects on the health and safety of humans. This training is required for any employee dealing with radioactive materials.

EHS 2047 Art Studio Safety

Art Studio safety is required for all employees and graduate students who work in art studios around campus. This course will help instill a safety culture that reduces accidents for employees and promote a safe work environment. This training also informs employees how and when to use many types of personal protective equipment.

EHS 2048 X-ray Safety

As CCU steadily grows we are fortunate to stay up-to-date with the latest technology. With these new devices there comes responsibly on the proper use and protection of the employee. This is a basic X-ray safety training designed to give general understanding of fundamentals of X-ray operation, potential hazards associated with X-ray equipment and ways to control the hazards.

EHS 2051 Hot Work Permit

Workers designated to operate welding, soldering, cutting and other hot work equipment shall be trained in the use of the equipment. Additionally, workers who operate welding equipment shall be properly instructed and qualified to operate the equipment. This training will discuss the appropriate safe hot work practices and procedures as delineated in the OSHA and NFPA standards. Prior to this training all employees must complete EHS 1035 Welding Cutting and Brazing (Hot Work) Safety.

EHS 2052 Coach the Van Driver (in-class)

This van driver training program presents comprehensive coverage of collision-prevention techniques. The training will cover: van characteristics & inspection, scanning, cushions of safety and communication, reading traffic situations and other materials in order to safety drive these heavier vehicles.

EHS 2056 Asbestos O&M (14 hr/in-class)

This 2-day OSHA Asbestos Operations and Maintenance (O&M) Initial Training Course (OSHA Class III) is designed for custodial and maintenance individuals who perform duties where asbestos-containing material (ACM) is likely to be disturbed. This course includes hands-on activities and provides an in depth understanding of asbestos, health effects, personal protective equipment, work practices and regulatory requirements. This asbestos operations and maintenance initial course fulfills training requirements for OSHA Class III work, for OSHA Competent Person for Classes III and IV, and AHERA O&M requirements.

Prerequisite for EHS 3056

EHS 2058 Laser Safety

This course is designed to teach LSOs administrative duties that will help them develop, implement and maintain laser safety programs while meeting the training requirements outlined by ANSI and OSHA, including: laser control measure and personal protective equipment, strategies that make laser safety program successful and effects of lasers on the eye and skin.

EHS 2059 Chipper/Shredder Training (in-class)

Chipper/Shredder Training will teach employees the important safety practices to be followed when operating. It will provide details to help you better understand the risks of incorrectly operating equipment as well as working in unsafe environments. The training will review the meaning of common warning signs and labels and identify the appropriate protective equipment.

EHS 2060 WPS Pesticide Training

This training will provide basic pesticide safety information to untrained workers before they enter a pesticide-treated area on the establishment. You will be provided the basic pesticide safety information in order to work with or around pesticides correctly to prevent pesticides from entering your body. The training will run through the correct clothing options to wear when working with the chemicals, how to wash/shower after, how pesticides can drift during the application and what to do if they enter into the body.

Prerequisite for EHS 3060

EHS 2061 Heat Stress Training

There are many times heat and humidity combined with strenuous activity can become dangerous if proper precautions are not taken. In order to help prevent any heat related injuries, this heat stress training is for employees that work several hours in hot environments. This training will show employees how to prevent and respond to serious heat-related problems by using prevention techniques; how to recognize the signs and symptoms of heat stress; and, what first aid procedures to administer when assisting victims with heat related illness.

EHS 2062 Silica Dust Training

Silica is a naturally occurring substance used in a wide variety of industries and construction operations, but it can be hazardous if workers are exposed to excessive amounts of silica dust. EHS 2062 will explain how to use personal protective equipment and how to apply safe-work practices to limit silica dust exposure.